All About Shrink Wrapping

Shrink wrapping is a versatile packaging technique that has revolutionized the way products are protected and presented. This method involves using heat to shrink a plastic film tightly around an item, creating a secure and visually appealing package. From protecting products during shipping to enhancing their shelf appeal, shrink wrapping has become a go-to solution for various industries.

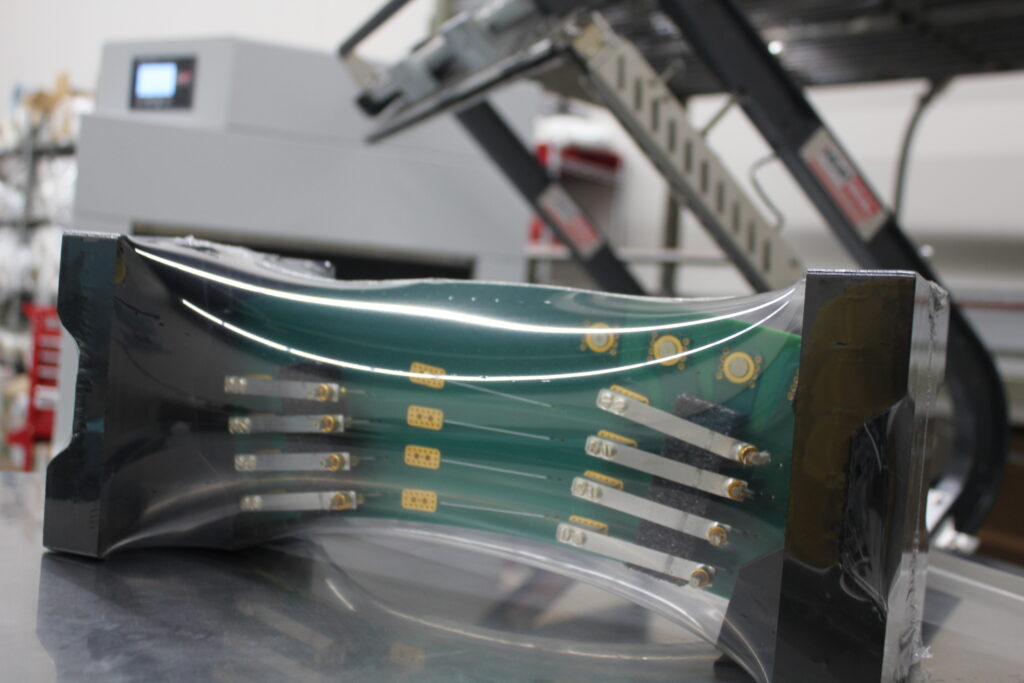

The primary material used in shrink wrapping is polyolefin or PVC film. When heat is applied, the plastic film shrinks uniformly around the product. This is achieved through a combination of heat and airflow, often generated by a shrink tunnel or heat gun. The heat activates the molecular properties of the film, causing it to contract and conform to the shape of the item.

Why Use Shrink Wrapping?

- Protection: Shrink wrapping provides a robust protective barrier against dust, moisture, and other environmental factors. This is particularly beneficial for products that may be sensitive to changes in humidity or temperature.

- Tamper Resistance: The tightly sealed film offers tamper-evident packaging, ensuring the integrity of the product. This is crucial for industries like food and pharmaceuticals, where safety and quality control are paramount.

- Cost-Effective: Shrink wrapping is a cost-effective solution compared to traditional packaging methods. The material costs are relatively low, and the efficiency of the process helps in reducing labor expenses.

- Enhanced Aesthetics: Shrink wrapping enhances the visual appeal of products, creating a sleek and professional appearance. This is particularly advantageous for retail items, as attractive packaging can influence consumer purchasing decisions.

Common Applications for Shrink Wrapping

- Bundling Products: Manufacturers often use shrink wrapping to bundle multiple products together, creating convenient and visually appealing multi-packs. This is common in industries such as beverage, home goods, and automotive.

- Food: Shrink wrap adds a protective layer which is also tamper-evident. Depending on the type of film used (perforated or non-perforated), it can also extend the shelf life.

- Print and Textile: Shrink wrapping is a popular choice for packaging printed products from books to t-shirts, providing a protective layer that prevents scratches and damage during transit.

- Industrial Products: Large and industrial items, such as machinery and equipment, can be shrink wrapped for protection during shipping and storage. The tight seal helps prevent corrosion and damage from environmental elements.