What type of packaging is it?

Clear, Form-Fitting Packaging. It’s not all the same.

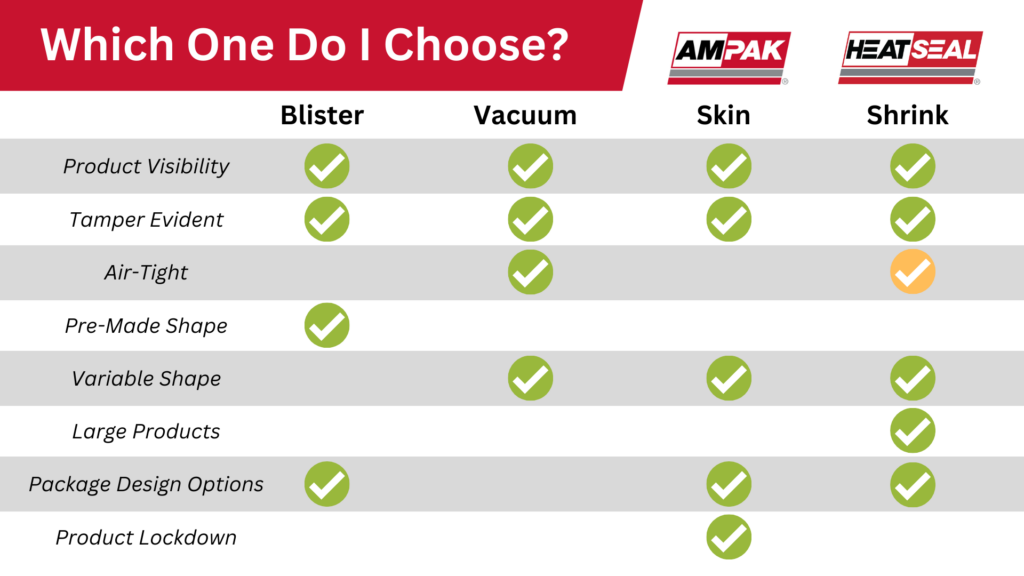

When you open a package, the first thing that comes to mind is probably not what type of packaging it’s in. However, when you’re looking to start packaging your own products, it’s important to know the difference. There are four main types of clear, form-fitting packaging used today: Blister Packaging, Vacuum Packaging, Shrink Wrapping, and Skin Packaging. Today we’ll see the positives and drawbacks of each type–and what kind of products are a good fit.

Blister Packaging

We all know this one. Blister packaging is a hard plastic shell put over a product and sealed to a substrate. It is used in a wide range of products from pharmaceuticals to children’s toys. The main appeal of blister packaging among the three is its compartmental style. Pre-formed molds make it easy to dose in the case of pills or parts kits, and it also helps protect products from being crushed during transit. This is why blister is often used for over-the-counter drugs, toys, and electronics.

Compared to shrink and skin packaging, blister packaging is the hardest to open, sometimes requiring scissors depending on the use case. When cut or torn apart, the hard plastic can create sharp edges which make opening your product a far-from-pleasant process. This is most commonly known as ‘wrap rage’. Another downside is that your product and package are not interchangeable. Pre-formed shells require the same product–the package cannot be used for anything else.

Vacuum Packaging

Most famous for preserving fresh food, the main benefit of vacuum packaging is creating an air-tight package. Models are available ranging from heavy duty commercial applications to at-home countertop units. Vacuum packaging involves placing the product in a pouch where all of the air is removed from the package from a single hole, which is then sealed by the machine to close the package.

While vacuum packaging is an excellent option for extending the shelf life of your food, its use in other areas is narrow at best. There are not many cases to use vacuum packaging outside of food wrapping. Even in cases of food wrapping, many will choose other options due to the speed, cost, and other complications. Vacuum requires a specific type of packaging, and even when done right requires significant time for the machine to remove the air. Sometimes the suction itself can pose a challenge, especially for products like fresh meat that may have liquid.

Shrink Wrapping

Versatile, fast, and easy. Shrink creates a tighter fit around your product than a blister shell, while also being a standalone package. First, the shrink wrap must be perforated to allow air flow. Shrink film can purchased with perforations, or you can use a perforator to create your own. After the product is placed in the shrink film, it is sealed on the edges to create a bag around it. When this film is exposed to heat, it will shrink down around the product, turning the bag into a tightly formed package. Perforations in the film allow the air to escape during this process.

The biggest advantage of shrink wrapping is its speed and versatility. While you may be constrained by certain dimensions (film width, heat tunnel height, seal area), shrink wrapping can be used for products of different shapes and sizes without needing to completely change your setup to accommodate. Products like Heat Seal’s one-step shrink and HDX-250 and 350 are easily adjustable so you can quickly switch configurations for different products.

Because shrink wrapping requires heat, cold environments and products may pose a challenge. This may cause difficulty during the shrinking process, as the film needs to heat up in order to create a tight fit. Furthermore, while it is possible to create an air-tight package with shrink wrapping, it requires an extra step.

Skin Packaging

Whereas vacuum packaging is mainly good for fresh food, skin packaging accomplishes a similar package for most other applications. The main difference between the two is that skin packaging does not create an airtight package. The process involves a porous substrate to allow air through, a product, and a film. First, the film is heated to become flexible. Air is sucked out from the bottom while the hot film is placed on top so it molds to the exact shape of the product. The film will only stick to itself and the card underneath–not the product.

Skin packaging completely immobilizes the product on the board, unlike blister packaging which gives some wiggle room. The final result is secured for shipping and can easily be packed into a box. This type of packaging excels with electronics, kitting, and high-value parts.

The Right Packaging For Your Product

Each type of packaging has its own strengths and weaknesses. When it comes to finding the right one for your product, it’s best to ask an expert! For Skin and Shrink packaging, Heat Seal offers top-of-the-line equipment backed by nation-wide service.